Description

Save steps, time and money by converting your existing bins, tanks or hoppers into accurate, dependable weighing systems with Avery Weigh-Tronix Weigh Bars and instrumentation.

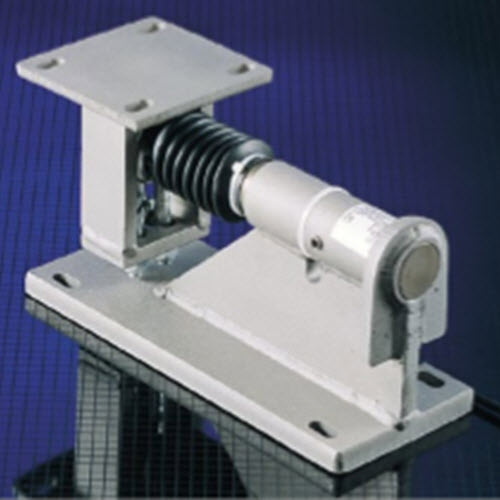

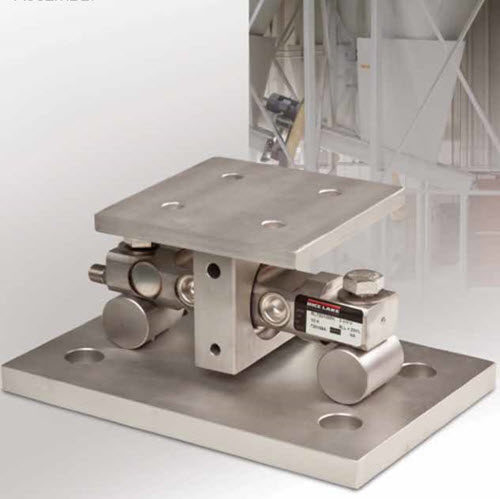

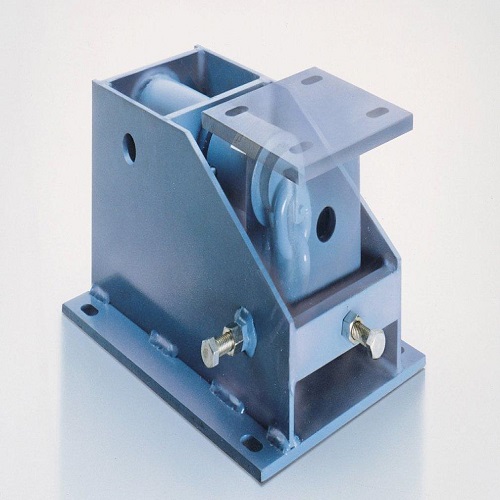

Wide selection of Weigh Bars®

Avery Weigh-Tronix weighing systems come in sealable (Class III, 5,000d) and non-sealable (0.25% accuracy) versions with capacities from 125 to 200,000 pounds. Avery Weigh-Tronix offers Weigh Bars for both basemounted and suspended installations. Standard Weigh Bars are finished with epoxy paint for corrosion protection. Stainless steel versions1 have also been developed for food processing and chemical applications. The chain link assemblies are well suited for food applications where thorough cleaning and sanitation are essential. With its unique self-leveling chain link design, the Avery Weigh-Tronix Weigh Bar is ideal for hoppers and silos where vibration and off-center loadings can sometimes be a problem.

Fast, inexpensive installation

The Avery Weigh-Tronix bulk weighing systems can be installed quickly and easily, with minimum disruption of your normal business. There are no stay rods to install, no moving parts to adjust or balance.

Remote weight indication

The digital weight indicator can be installed anywhere you want it, at the weighing site or at a supervisory station up to 400 feet away. In addition, accessory remote displays with large, 4-inch or 6-inch high digits are available.

Minimal servicing costs

Because the system is all electronic, with no shock sensitive check rods or delicate moving parts to keep adjusted, maintenance is kept to a minimum. This saves you money, not only in service charges, but also in system downtime. Multiple bin weighing Optional selector boxes make it possible to monitor several bins, one at a time, with a single indicator.