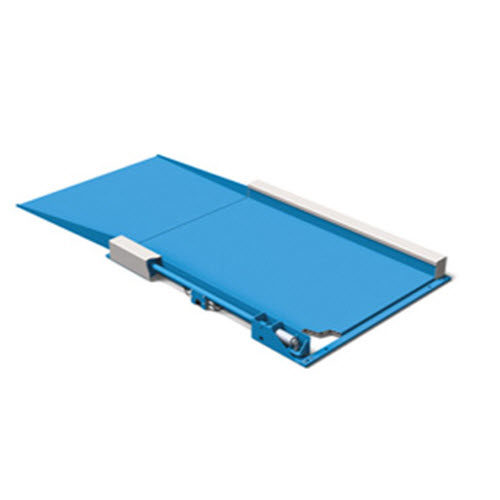

General

Perhaps the most robust deck scale on the market today, the DS from Avery Weigh-Tronix has stood the test of time in some of the world’s most demanding weighing applications. Known for its longevity and trouble-free operation, the rugged overload stop design of the DS has been tested time and time again to withstand some of the harshest and most severe conditions – a unique attribute that helps mitigate the high service and repair costs that are associated with less robustly engineered floor scales.

Design

High steel content – With more steel content than the average deck, the DS is engineered to withstand the most intensive and even abusive operating conditions.

Built to last – The DS comes with high strength steel deck plates designed to provide superior rigidity. The deck plates are welded to internal steel channels providing greater support and robustness. All cables are protected within the deck to eliminate potential damage to wiring. This reduces downtime, maintenance charges, and extends the life of the scale.

Exceptional accuracy – The DS is fitted with a Weigh Bar® designed to exceed the accuracy levels of a traditional load cell. The Weigh Bar is rugged, reliable and highly precise. Validated with in-house rigorous test analysis, the Weigh Bar provides the precision needed to help substantiate critical business decisions.

Unique chain link design – The unique chain link suspension system allows operators to place deck load on the Weigh Bar while minimizing extraneous side and end loads. This results in improved accuracy and scale performance. The chain links also absorb shock loads rather than transfer them to the Weigh Bar.

Side impact protection – The DS includes side and end stop plates which were designed to overcome potential side impact from damaging the Weigh Bar.

Fast and simple to install – The chain link on the DS includes “U” bolts which have an adjustable leveling design. This allows for a quick and easy installation.

Pit mounting – When space becomes a constraint, the DS provides the versatility and flexibility of pit mounting to provide a central location for weighing.

Axle loading – The DS axle load rating is 50%: 5,000 lb for a 10,000 lb scale; 10,000 lb for 20,000 lb capacity; and 25,000 lb for 50,000 lb capacity scales.

Construction: welded support channels. All cables protected within the deck to eliminate potential damage to wiring.

2,000/5,000/10,000 lb capacity: 3 ⁄ 16″ top plate

Weight sensors: Four Weigh Bars*

Weigh Bar output: 1 or 2mV/V

Excitation: Up to 20 VDC (generated by the weight display)

Lifting positions: Over 48″ – 2 lifting eyes each on the short side of the scale.

Lifting eye size: .38-16 UNC or 0.5-13 UNC

Overload protection: 200%

End loading: 100%

Temperature: 14 to 104°F (-10 to 40°C)

Agencies:

NTEP Certificate of Conformance #88-221, legal-for-trade at 5,000 divisions

Factory Mutual approved Weigh Bars and junction box

Add a GSE Model 350IS or 355IS Indicator for a complete system with Factory Mutual approval.

Resolution:

Industrial Applications: 5,000 divisions

Non-Industrial Applications: 10,000 divisions

Interface cable: 25 ft cable included